Tsunoda’s high-quality products and services are made possible by its parts processing technology.

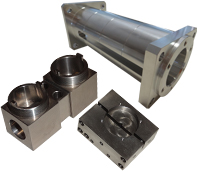

Tsunoda Co., Ltd. was founded to handle metal parts machining projects that mainly involved cutting jobs at first. Tsunoda has expanded the scope of its operations since and currently handles not only metal parts fabrication projects at the request of customers but also manufactures most of its own products in house (including labor-saving machines and equipment, and various functional modules). Parts manufactured by Tsunoda are currently used in diverse applications, both as individual parts and as finished products.

Machining capability overview

-

- Machinable size range

- Minimum: in 1-mm units; maximum: approx. 1500 mm

-

- Machining precision

- In the order of microns

-

- Machinable materials

- Tsunoda has the know-how to handle machining jobs on a wide range of materials, from soft and delicate materials such as aluminum to difficult-to-cut materials such as stainless steel, titanium, Inconel.

Want to order parts machining by Tsunoda?

Even if you have no schematic drawings or specification documents, Tsunoda’s technical team can handle your order.

Tsunoda’s engineering team is highly competent at creating design plans from actual objects or hand drawings,

and machining parts based on them. It welcomes orders of any quantities, starting from a single unit.

Because it has one-stop in-house production capability, Tsunoda can flexibly adapt to delivery schedules.

Please feel free to contact us for a consultation, even if urgent delivery is required.

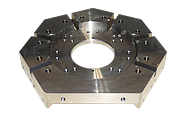

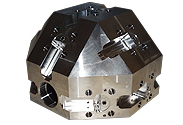

Machined AL parts

Machined AL parts

Machined AL parts

Machined AL parts

Machined AL parts

Machined AL parts

Machined AL parts

Machined AL parts

Machined AL parts

Machined AL parts

Machined AL parts

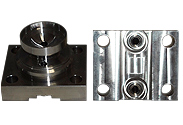

Machined SUS parts

Machined SUS parts

Machined SUS parts

Machined SUS parts

Machined SUS parts

Machined SUS parts

Machined SUS parts

Machined SUS parts

Machined SUS parts

Machined SUS parts

Machined SUS parts

Machined SUS parts